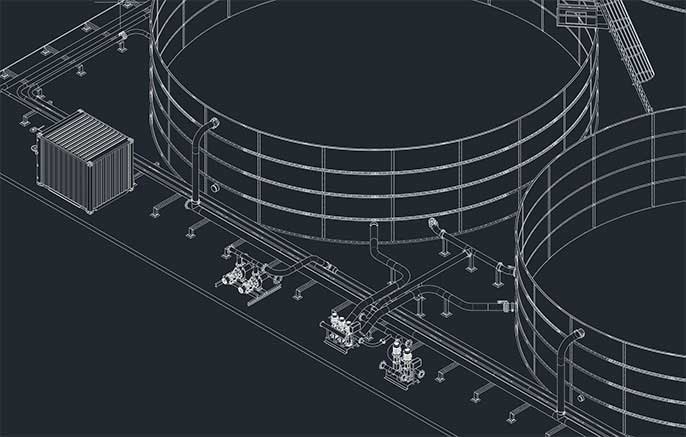

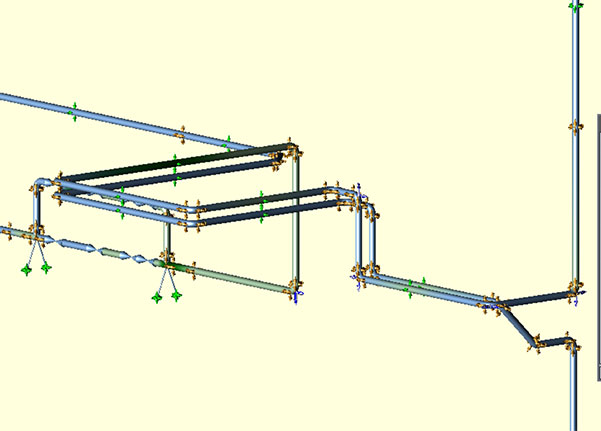

Pump & Flow focuses on providing pumping solutions for the mineral resources industry. We design, supply, construct and commission piping systems, and optimise existing infrastructure to improve the efficiency of your plant.

- Tailing systems

- Dewatering schemes

- Slurry flows

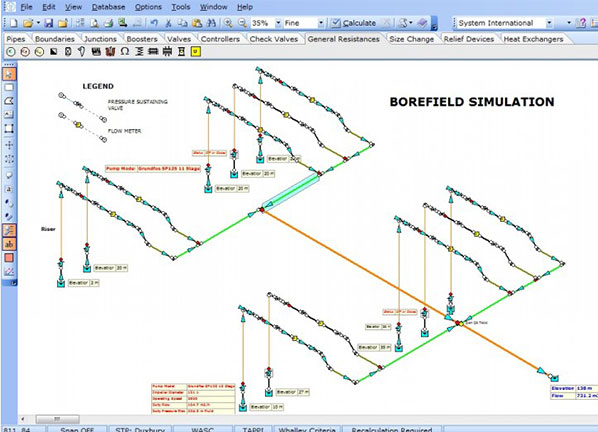

- Borefields

- Fire protection

- Paste backfill

- Underground pump stations

- Utilities and reagents

- Sampling and lab work

- Dust suppression

- Pipeline inspection and leak detection

- Mine water boosting and transport

- Waste water treatment

- Mapping undocumented networks

- Debottlenecking and optimisation

We pride ourselves on a cost-effective and practical approach to deliver outstanding value to greenfield or brownfield projects. For plants already in operation, we are also fully equipped to evaluate existing systems and networks, and offer debottlenecking advice and optimisation strategies.